The History of Mitsubishi motorsports, Ralliart and how to translate a book with your phone

I bought another book on Yahoo Auctions Japan. It’s the third one from the same publisher, JAF. The book is called Rally Maker Series and they do a fantastic job naming the people involved in each project, describing the engineering process behind the cars and adding lots of layers to stories that are generally lost in time. Here’s the second effort I’ve put in. The first was about the Pajero. I’ll try to capture that at a later date.

The book starts in the early days of 2wd rallying first in Japan, then in the UK with Andrew Cowan. I might translate the early years at a later time but my interest is mostly in Group A, and how we got there so I started focusing on the time just before Group A, the time when Mitsubishi used the Lancer Turbo2000, a RWD car with a 2.0 liter 4g63 engine that had a weak-ass SOHC cylinder head but a respectably large turbo that made up for it’s lack of valves and visual symmetry.

Just look at that bad mofo. They took the standard lights off the car as well as the nose and instantly made it look 100 times better.

A few of you may have seen photos of this car with little context attached, obviously it's a really striking design, a Starion with the nose chopped off "crudely" as described by a lead engineer from Mitsubishi at the time. Research into a developing 4wd Group B competitor began after Mitsubishi Observed Audi's domination in the early 80s. Mr. Kumi Yamamoto from Mitsubishi's Okazaki Technical center was the lead man on the project, his challenge- how to develop and then to homologate a car quickly was entirely up to him and his team. This is perhaps the least talked about car in Mitsubishi's history and at the same time, the most critically important in how it held crucial technology and set the path for future project workflows that even seeped into the Dakar Prototypes at SBM. Development at the technical center started with a switchable dogbox that had a 2wd-4wd switch. Some Mitsubishi Enthusiasts might remember a W5m33 JDM box with a similar switch. The problem was the early cars, with their crude 4wd could not turn in well and the idea for this Starion was that drivers would switch to 2wd for tight turns. This proved too complicated for drivers and during the development, Yamamoto knew they needed a new plan. Where did they go?

Yamamoto used his UK connections and opened talks with UK farm equipment supplier Ferguson & Co. who had an interesting viscous coupling device used in farm implements, generally on lower power vehicles and certainly not on 400hp rally cars. The connection was made and Mitsubishi began collaborative testing on the units. These couplings went into the competition car and with some adaptation of Pajero parts, using Magnesium cases over Aluminum and lighter weight shafts they were able to reduce the transmission weight by 25kg. Things were looking good. The team was learning to iterate quickly and the foundational technologies for the Galant Vr-4 and later, the Evo were being developed on this Starion. The car was entered in 1984 RAC under what was a Prototype class, Group S. It suffered some suspension problems and for one reason or another didn't race again until the Malaysian Rally in 1985, again in the S class. The production cars never materialized but parts were actually produced. It sounds like there wasn't confidence in the economy to sell 200 and the writing may have been on the wall for Group B by that time.

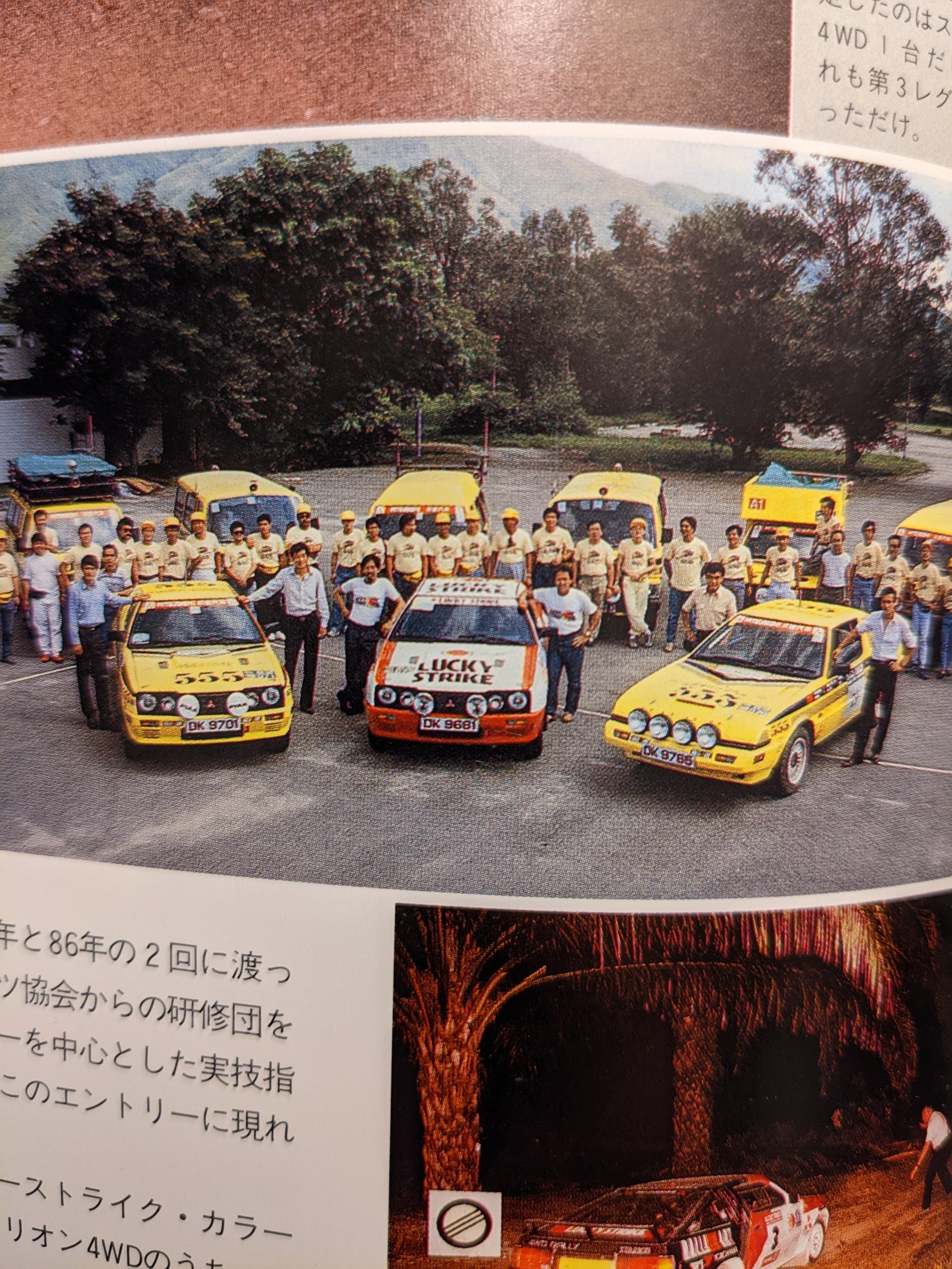

I will leave you with this final tidbit. This book suggests the unique color of the car to be a reference to the "555 Tobacco color of the time" if only we knew what this meant, or what could have been. In fact, when the car raced it’s last event in China, the whole team did so with a 555 livery.

Here are a few more photos of the car. The drivetrain was a modified Pajero setup but with a VCU and a Magnesium case. The Transfer case had to be clearanced from above by a big bulge in the driveshaft tunnel. Drivers complained of burns during testing. The engine sported a 19c turbocharger that was a victim of it’s own spinny-ness early on, breaking itself to bits and cracking the manifold below. Technicians struggled to replace it during the rally due to the heat and it was improved upon during development with new materials.